The production of aircraft engine parts requires extensive radiographic testing to comply with quality and safety regulations. The time consuming film radiography of welds is increasingly replaced by automated digital radiography solutions using digital flat panels and automatic image processing.

Microfocus X-ray sources allow to analyze welds at high resolution using magnification in the range of 2x to 10x. X-RAY WorX developed a series of high resolution rod anode tubes to comply with the EN 17636-2 standard that support a wide range of aerospace inspection tasks.

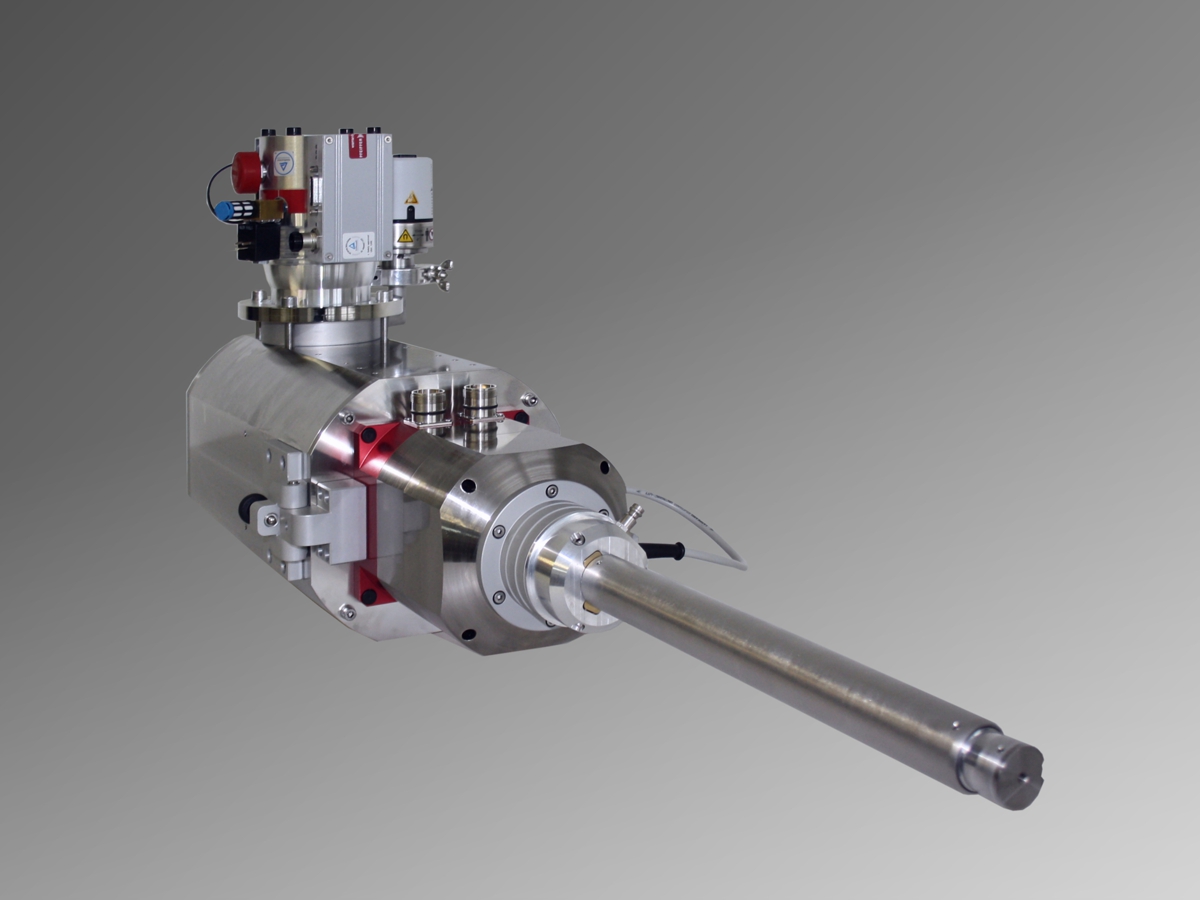

Microfocus X-ray tube XWT-225-RAC

Rod anode tubes are applied to inspect various engine parts with small diameter clearance that require single wall penetration. The flexible design of X-RAY WorX rod anode tubes allows the application of panoramic exposure using RT and CR but also digital radiography with cone beam exposure.

The targets respectively tube heads of X-RAY WorX rod anode tubes can be easily exchanged to switch from panoramic to cone beam exposure. Further-more tools are offered to support alignment and calibration of rod anode tubes and to measure the focal spot size according to EN12543-5.

Microfocus X-ray tube XWT-225-RACX-RAY WorX rod anode tubes have been implemented in several customized DR solutions by partners of X-RAY WorX around the globe.

To find out how X-RAY WorX solutions can optimize your inspection tasks, contact one of our representatives or X-RAY WorX directly.