Industries applying microfocus X-ray inspections

X-ray inspection in automotive industry

High resolution X-ray inspection and increasingly microfocus computed tomography assure the quality of safety-related components in modern cars.

These include chassis frame components made of light metal alloys and car body parts from compound materials that should help to save weight and increase the energy efficiency of the car. Furthermore advanced driver assistance systems (ADAS), efficient drive concepts with hybrid engines or electric engines, and their energy supply (high power batteries and electronics, IGBTs).

- Electronic assemblies

- Electronic control units

- Micro-mechanical devices

- Plugs and crimps

- Battery packs

X-ray inspection in aerospace industry

Recommended product lines: THE Plus, SE, RA, RAC, RAC Superfocus

Microfocus X-ray technology plays an important role in the inspection of mechanical components like light alloy castings, parts of aircraft turbines or actuators. The trend towards miniaturization produces smaller and lighter parts to reduce weight and save material.

At each stage of the production quality requirements are increasing. The tolerances for defects are going down to only a few microns (1 µm = 1/1000 mm).

- Mechanical components like control valves or flap actuators

- Circumferential electron beam (EB) welds in conducts and air ducts

- Rotor blades, turbine blades

- Aircraft turbines

- Electronic assemblies

- (Small) titanium and aluminium castings

- Composite materials

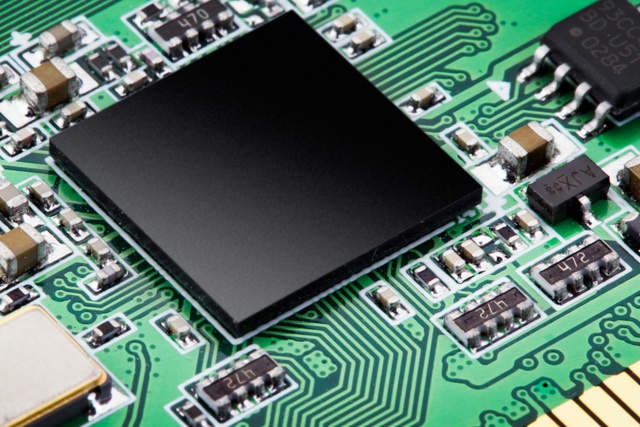

X-ray inspection in electronics industry

The microfocus X-ray inspection of electrical interconnects in semiconductor and electronics production has become a standard after the introduction of electronic packages like Ball-Grid-Arrays (BGA) and Quad-Flat-No-Leads-Packages (QFN).

Increasingly complex products like Package on Package (PoP) or Fine Pitch Ball Grid Array Stacked Die (FBGA-SD) have intensified the requirements regarding accuracy and resolution. Also assembled and bare multilayer printed circuit boards (MLPCBs) with up to 48 layers or printed circuit boards with embedded layers of copper require special testing facilities that are equipped with powerful microfocus X-ray tubes.

- Ball Grid Arrays (BGA), integrated circuits (IC), bond wires

- Semiconductor packaging (diodes, wafer bumps, copper)

- Shielded devices, housings, complete modules

- Wafer-level chips scale packages (WLCSP)

- Quad-Flat-Packages no-leads (QFN), similar components

- Printed circuit boards, hidden interconnects

- Bare boards, multilayer boards

- Power modules, IGBT modules

X-ray inspection in energy industry

Recommended product lines: THE, RA, RAC, RAC Superfocus

All components involved in this process need to be carefully controlled by using different X-ray inspection techniques. Microfocus X-ray inspection is involved where the accessibility is difficult or the acceptable defect sizes fall below certain limits.

- Wind power stations (power converters, IGCT, IGBT)

- Pressure valves and pressure vessels (weld seams)

- Gas turbines (weld seams)

- Tube-to-tubesheet (TTS) welds of heat exchangers

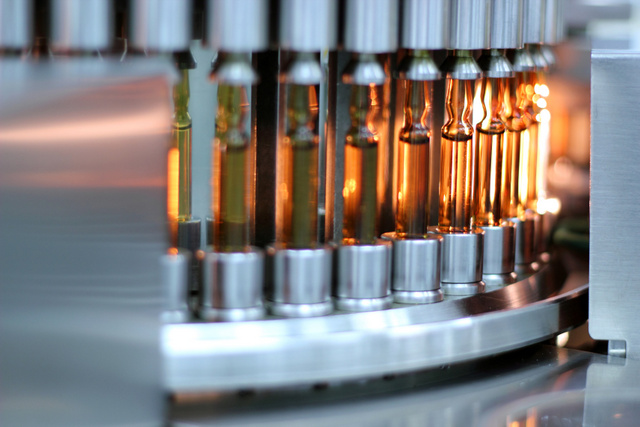

X-ray inspection in medical industry

- Medical devices like pacemakers or implantable cardioverter-defibrillator (ICD)

- Titanium and ceramics-implants

- Stents

- Syringes

- Inhalers

- Vaccine vials

X-ray inspection in scientific institutions

The investigation of scientific samples and prototypes using microfocus computed tomography is very common. It allows the non-destructive visual analysis of structures and is the base for simulations of different environmental conditions like pressure and temperature.

Examples are the flow of water in rock or the dissociation of methane hydrate. The production method and composition of valuable historical artefacts can be discovered using high resolution X-ray systems. Applications can be found in several domains like material science, archaeology, geology, biology and physics.

- Plastics, ceramics, light alloys

- Compounds, fibre reinforced materials

- Organic materials, seeds, tree trunks

- Soils, ice drilling cores

- Concrete, rocks

- Archaeological finds, paintings, statues

- Superconductive material