Microfocus Technology

Magnification and unsharpness

The electron beam generates X-ray radiation in the tungsten layer. As useful radiation we use a cone beam that is emitted through the transmission target. The opening angle of the cone beam is approximately 170°. It can be limited to arbitrary angles by apertures.

The thickness of the transmission target has a significant impact on the maximum magnification in X-ray microscopy, which is high magnification two-dimensional radiography or radioscopy. The closer the part under inspection is positioned at the source of radiation the higher the geometric magnification. The thinner the target the higher the geometric magnification that can be achieved for a given, fixed focus-detector distance.

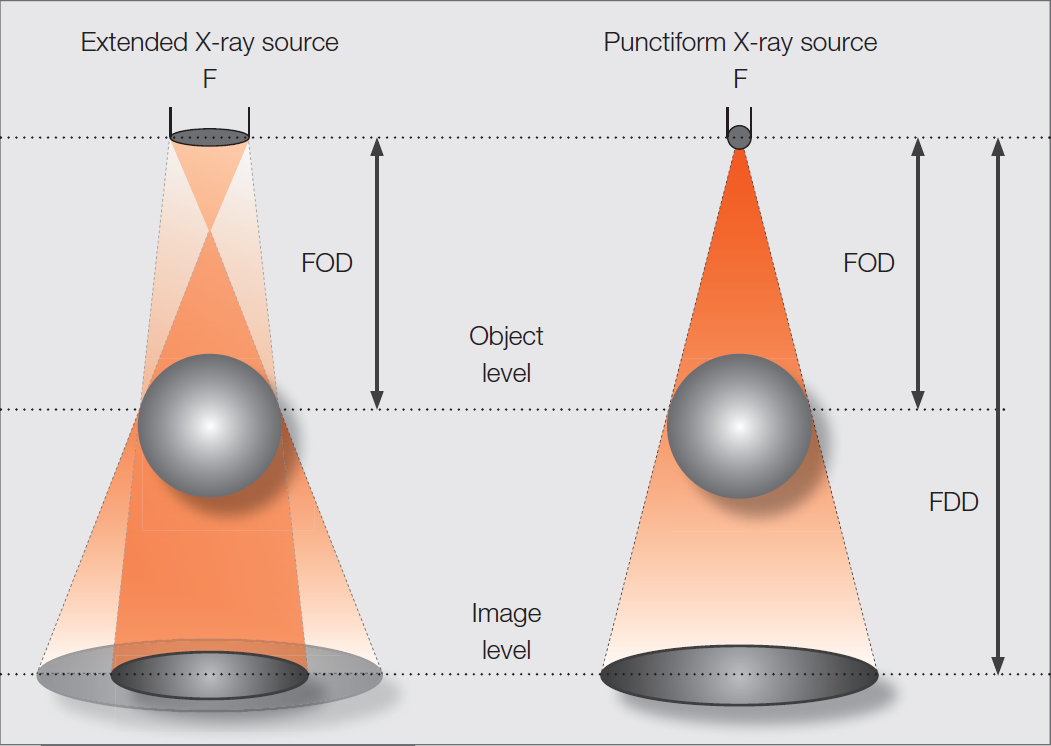

- Geometric magnification (M) is required to visualize very small details. It is defined by the ratio of focus-to-detector distance (FDD) and focus-to-object distance (FOD).

- Geometric unsharpness (U) is introduced by the X-ray focal spot. A bigger focal spot size (F) leads to higher unsharpness by generating a wider half shadow (penumbra) of the object.

- FOD: Focus-Object-Distance

- FDD: Focus-Detector-Distance

- F: Focal Spot Size

- Geometric unsharpness: U = (M-1)*F

- Geometric magnification: M = FDD / FOD

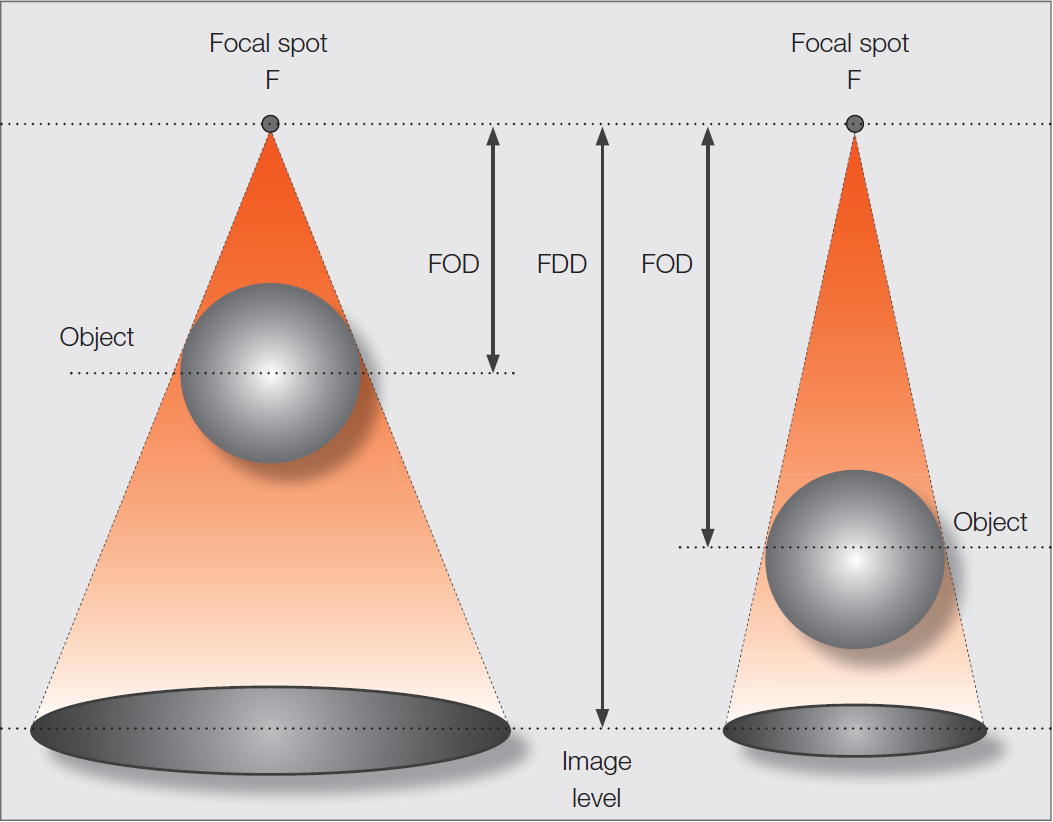

Geometric Magnification

- FOD: Focus-Object-Distance

- FDD: Focus-Detector-Distance

- F: Focal Spot Size

- Geometric unsharpness: U = (M-1)*F

- Geometric magnification: M = FDD / FOD

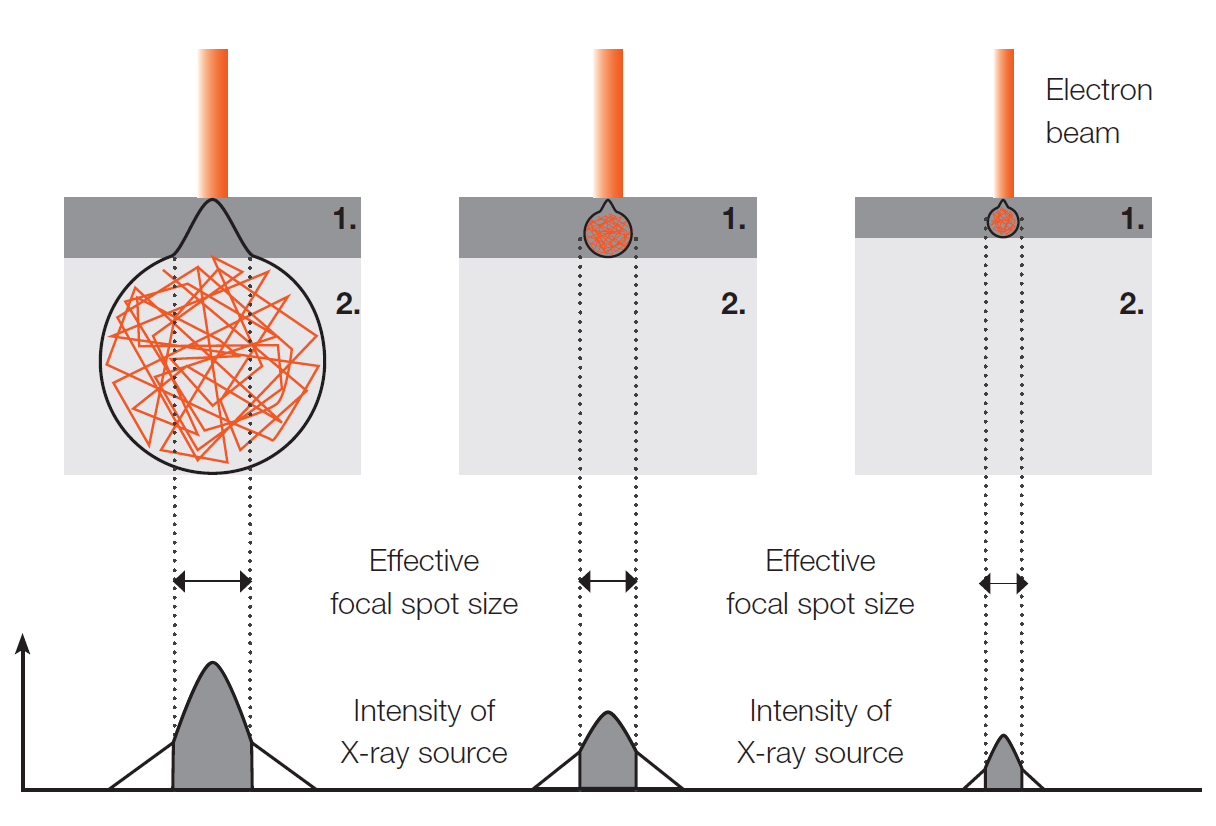

Effective focal size

- The effective focal spot size is influenced by the electron energy, the scattering volume, and the target material.

- At high acceleration voltages the electrons deeply penetrate the target. They scatter in the active target material with high atomic number (e.g. tungsten) during deceleration. This leads to an effective focal spot with significantly bigger dimension than the dimension of the electron beam.

- Electrons that are decelerated in the target substrate with low atomic number (e.g. beryllium) generate photons of higher wave length that might be partly absorbed by the target itself.

- At lower acceleration energies the electrons are decelerated closer to the target surface. They generate a smaller scattering volume and a smaller effective focal spot.

- Decreasing the thickness of the active target material leads to a smaller effective focal spot.

- Active target material: e.g. tungsten, copper, chromium, silver

- Target backing material: e.g. diamond, aluminum, beryllium (Material with low density)

Microfocus X-ray tubes

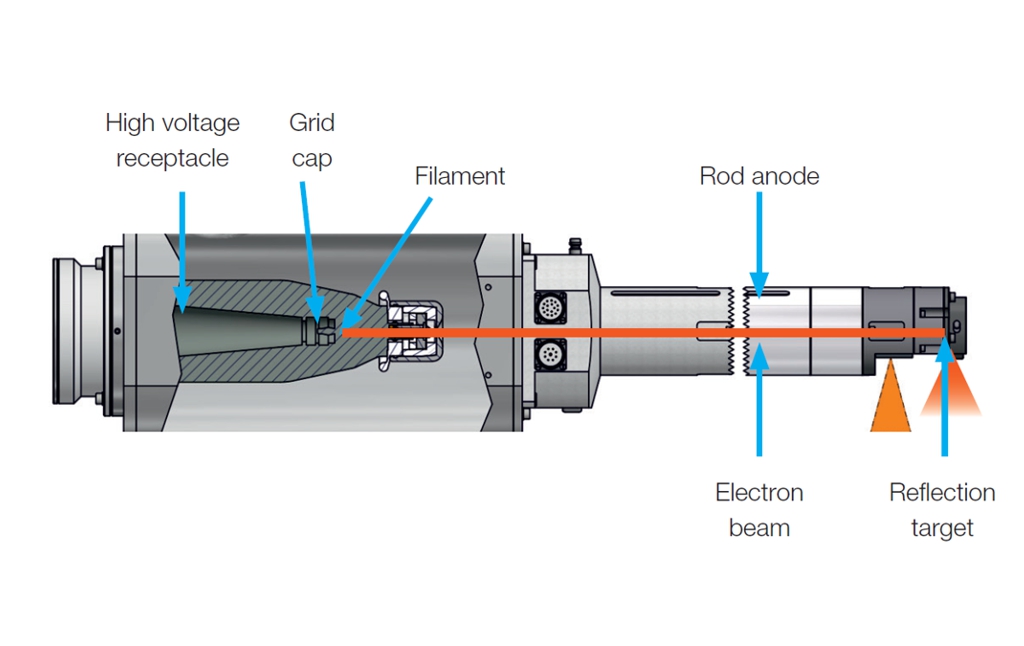

To cover different applications we distinguish three types of microfocus X-ray tubes. In the area of high resolution analysis with very high magnification tubes with transmission tube head are used. If higher power is needed, when e.g. analyzing dense, mostly metallic materials, tubes with reflection or directional tube heads are applied. Rod anode tubes serve for the positioning of the X-ray source at places that are not easily accessible, e.g. inside mechanical components or tubes. The three types of X-ray tubes described in detail on the following pages.

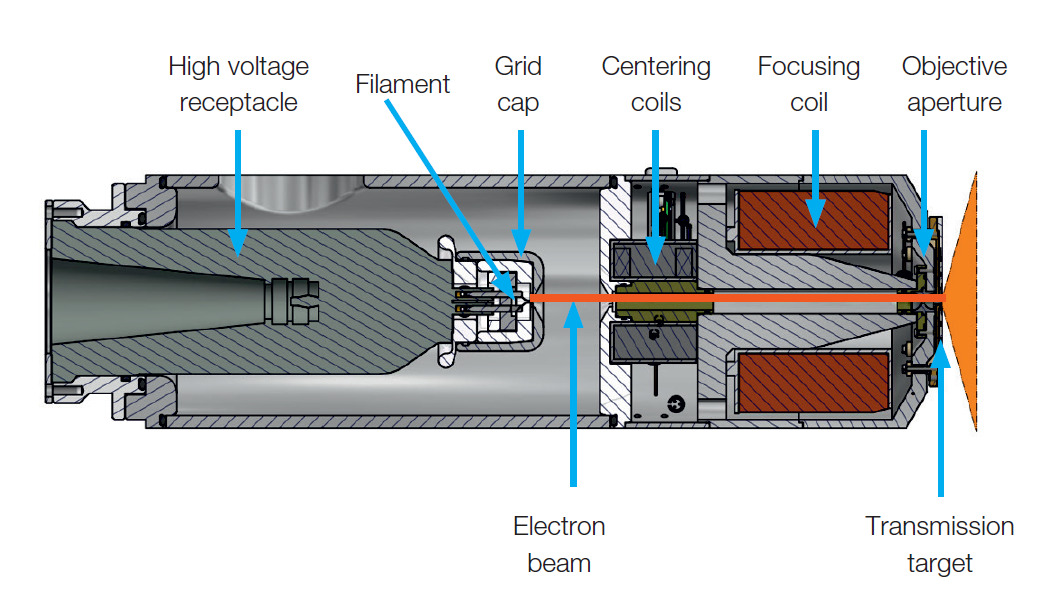

The head of an X-ray transmission tube contains a slide-like “target”, which is covered with a very thin layer of tungsten. This layer has a thickness of 1 – 10 microns, depending on the application of the X-ray tube. For special tasks different materials can be used for this layer. Which type of transmission target and which materials are best suited for your application? Have a look at the section Transmission Targets. The transmission target is hit by a focused electron beam in the so-called focal spot. See the graphics for reference. The size of this focal spot defines the sharpness of the resulting X-ray image. The bigger the focal spot the higher the geometric unsharpness. For high resolution X-ray analysis a small focal spot is inevitable.

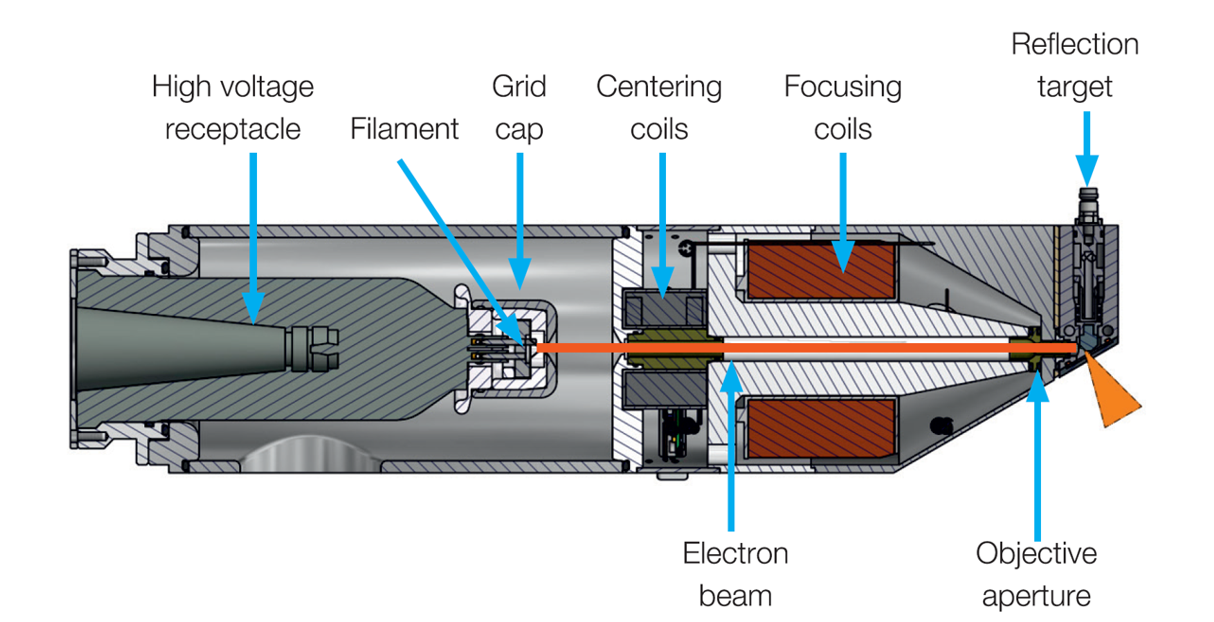

The reflection tube or directional tube includes a massive metal target. The integrated cooling of the target allows much higher electron consumption than a transmission target. The useful radiation is reflected in 60° with respect to the direction of the electron beam. The reflected cone beam is limited to approx. 30° by the tube window.

Microfocus transmission tubes – single stage

- High resolution applications in electronics, automotive, medical, and aerospace industries.

- Down to 2 µm JIMA resolution.

- Unsurpassed target power with target cooling and High Energy Target to reduce scanning time for computed tomography (CT), computed laminography (CL), and dimensional measurement (DM) applications.

- Stability of focal spot and intensity by optimized cooling of tube head and target.

- Single stage electron optics with centering and focusing coils.

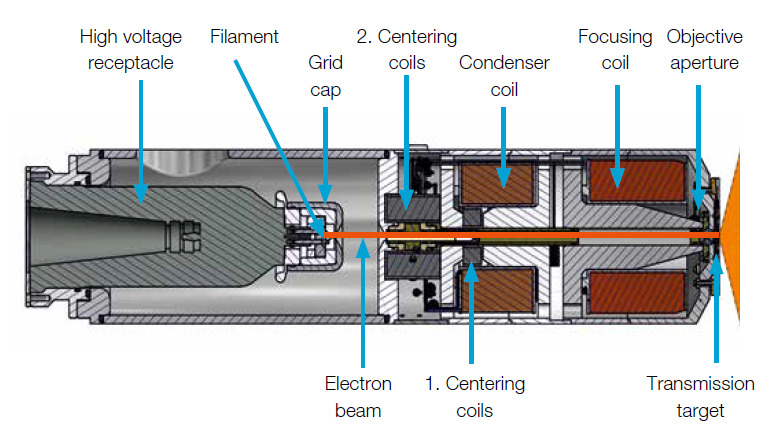

Microfocus transmission tubes – double stage

- Highest resolution applications in semiconductor industry and material science.

- Down to 0.5 µm JIMA resolution with High Resolution Diamond Target for computed tomography (CT) in the sub-micron range.

- Geometric magnification up to 4.000 x (at 100 cm FDD).

- Internal cooling of electron optics of product line TCNF.

- Double stage electron optics with condenser, two centering coils, and focusing coils.

Microfocus reflection tubes

- High power computed tomography (CT) and digital radiography (DR) applications in automotive, energy, and aerospace industries.

Down to 2 µm JIMA resolution. - Paramount target power and acceleration voltage.

- Long term stability guaranteed by optimized cooling of tube head and target.

- Flexibility by exchangeable tube heads and rod anodes.

- The distance between the focal spot and the outer side of the tube window is higher with the reflection tube than with the transmission tube. Thus the geometric magnification that can be achieved is higher with a transmission tube.

Microfocus rod anode tubes

Rod anode tubes play a key role for non-destructive testing in many industries. Their small focal spot allows high resolution results.

- High resolution digital radiography (DR) applications in automotive, energy, and aerospace industries.

- Support of digital radiography (DR) applications according to EN 17636-2.

- Flexible rod anode solutions with up to 1.5 m length.

- Exchangeable tube heads with panoramic, reflection, or transmission target.